Higher than expected lateral loads the root cause of issues with Ottawa LRT axles, Alstom says

The issues with the axle hub assembly on Ottawa's light-rail transit vehicles are due to the higher than expected lateral loads on the vehicle's axles during operation, according to Alstom.

The Transit Commission was told that Rideau Transit Maintenance and Alstom are not on the same page yet for the root cause of the axle issues, but the companies agree on several steps for a "sustainable solution" to mitigate the loads at the wheel-rail interface, including top-of-rail lubrication of the rail line.

Officials from OC Transpo, Rideau Transit Maintenance and Alstom delivered a report on the root cause review of the axle bearing issues on the O-Train vehicles since 2021. There have been three major incidents related to the wheel hub and axle-bearing since August 2021, including a derailment of an LRT vehicle at Tunney's Pasture station. O-Train service was interrupted for 28 days in July and August after a routine inspection discovered excess grease on an axle hub assembly.

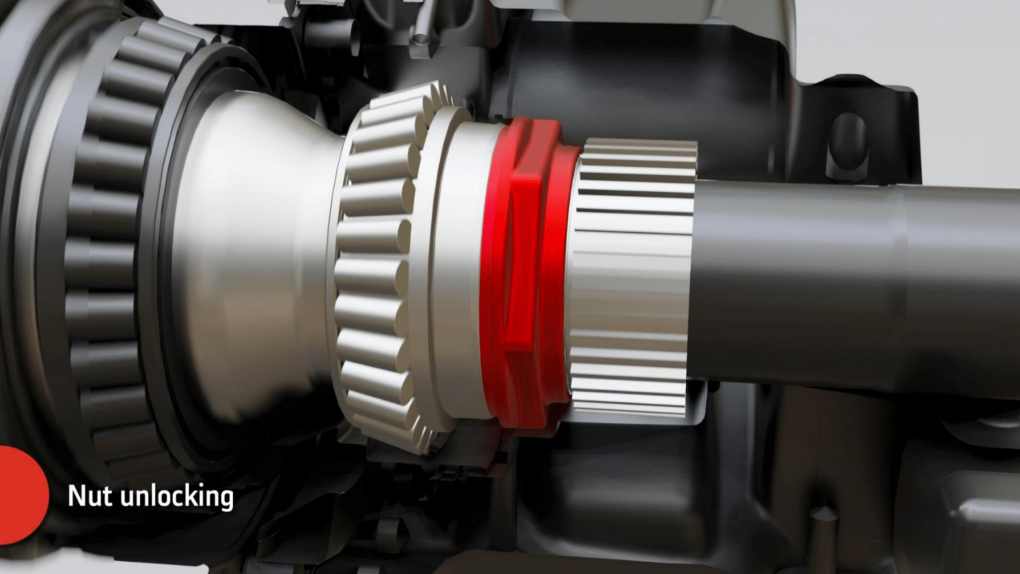

Staff told the Transit Commission that Alstom engineers have determined that the restraining nut that provides preload to the stack of bearings and spaces within the axle cartridge can "unlock", and Alstom has submitted a proposal to the city to modify the nut by inserting restraining pins "to prevent unlocking of the nut."

Alstom says its root cause investigation found "higher than expected lateral loads" on the wheel hub assembly, adding that conclusion would guide the manufacturer with the short-term and long-term solutions to the problem with the axles.

Alstom officials told the Transit Commission that the lateral loads (the dynamic at the wheel/rail interface) experienced by the wheel assembly during operation exceed design limits, causing bending loads on the axle hub assembly and leading to development of play into the assembly, the restraining nut unscrewing and a derailment.

"This failure mode that we see here in Ottawa we have not observed in our other fleets around the world," David Van der Wee, vice-president of Alstom, told the Transit Commission on Thursday.

- The information you need to know, sent directly to you: Download the CTV News App

- Sign up now for our nightly CTV News Ottawa newsletter

Van der Wee and Rideau Transit Maintenance both said there no agreement yet on the root cause of the axle hub bearing assembly, as Rideau Transit Group and Rideau Transit Maintenance continue its investigation.

"One of the key things that everyone agrees about is the nut coming unscrewed as being a key portion of that and how that needs to be a focal point no matter what is the sequence of events that brings the nut to being unscrewed," Van der Wee said.

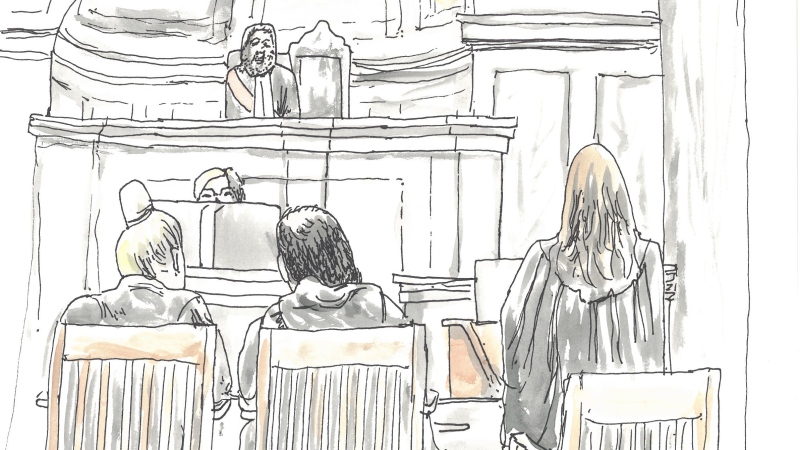

Alstom released pictures of the axle of an Ottawa LRT vehicle and the nut unlocking. (City of Ottawa/report)

Alstom released pictures of the axle of an Ottawa LRT vehicle and the nut unlocking. (City of Ottawa/report)

Alstom says the solutions to the lateral loads on the wheel assembly include top-of-rail lubrication and "coefficient of friction management," improving the infrastructure to limit the loads and increasing wheel assembly design limits.

Alstom has submitted several recommendations to Rideau Transit Maintenance for a sustainable solution to the issue, including moving the restraining rail, the deployment of top-of-rail friction modifier, ballast shoulders improvement and replacing the existing soft rail with harder rail.

Rideau Transit Maintenance told the Transit Commission the top-of-rail lubrication is a water-based product and is environmentally friendly. Data showed a 40 per cent reduction on lateral loads using top-of-rail lubrication along the O-Train line.

Alstom has also developed an improvement to the axle for nut locking, which will prevent the nut from unscrewing. Staff say the implementation of the nut locking would reduce the current inspection regime from the current 60,000 km to 400,000 km, which would increase the size of the fleet. Alstom's return-to-service plan included replacing the front and rear axles every 60,000 km, forcing OC Transpo and Rideau Transit Group to limit the number of trains operating to single-car service for most of the day.

Alstom's "roadmap to a sustainable solution" says the nut locking solution will result in improved service and the top of rail lubricant deployment will increase the hub life expectancy.

However, Rideau Transit Group says it does not agree with the root cause "just yet."

"We have technical concurrence on the part from the nut losing preload and then unscrewing. We need to focus on the work on how the axle-play gets generated; how do the parts start moving within the cartridge," RTG president Nicholas Tauchon said.

"We may get to an agreement with Alstom on their theory, but we're not quite ready to go there yet."

Rideau Transit Group says the top of rail modification system is targeted at 31 locations across the Confederation Line. The benefits of the top-of-rail friction include mitigating noise, mitigation corrugation damage and reduce rail/wheel wear and tear.

Councillors were told RTM, Alstom and the National Research Council are looking at optimization of the wheel-to-rail interface, including evaluating the wheel profiles and rail profiles.

Alstom is adamant its vehicle is suitable for the system, and the vehicles were designed with a full understanding of the LRT layout.

"There is unexpected, high lateral loads," Van der Wee said. "The part that we are absolutely aligned and in full agreement on is that we have a path forward to reduce those lateral loads. We are exploring a path forward to increase the resistance to those lateral loads, and this is a system-level approach to a system-level issue."

Additional improvements under investigation include replacing rails in curves with a harder rail, extending the restraining rail and reducing track buckling. A decision on those options is expected before the end of the year, with implementation next spring and summer.

Van der Wee told reporters that the lateral forces are coming from a "multitude of factors", and Alstom and RTG are "starting to address those factors one-by-one.

One of the nine recommendations submitted by Alstom to address the load issues is replacing the existing soft rail with a harder rail at curves and improving the ballast shoulders.

Rideau Transit Group says replacing the rails with a harder rail is under investigation, and any changes of that magnitude would require a lengthy shutdown.

Wheel hub design

OC Transpo and Rideau Transit Maintenance announced in July that RTG/RTM and Alstom agreed to redesign the wheel hub in a bid to resolve the issues with the axles.

Alstom says the axle improvement will look at increasing the contact pressure and improve material characteristics (surface heat treatment).

A timeline for the axle redesign presented by Alstom calls for the prototype completion and start of endurance testing in August 2025. The endurance and fatigue testing is not expected to be completed until mid-2026.

With files from CTV News Ottawa's Ted Raymond

CTVNews.ca Top Stories

Freeland previews omnibus budget bill, proposed capital gains tax change left out

Deputy Prime Minister and Finance Minister Chrystia Freeland will be tabling yet another omnibus bill to pass a sweeping range of measures promised in her April 16 federal budget, though left out of the legislation is the government's proposed capital gains tax change.

Man dies after suffering cardiac arrest while waiting in ER, widow wants investigation

When an ambulance took David Lippert to the hospital in March of 2023, the 68-year-old Kitchener, Ont., executive was hoping to find out why he was feeling weak and unable to walk. Some 24 hours later, he was found unresponsive in the ER.

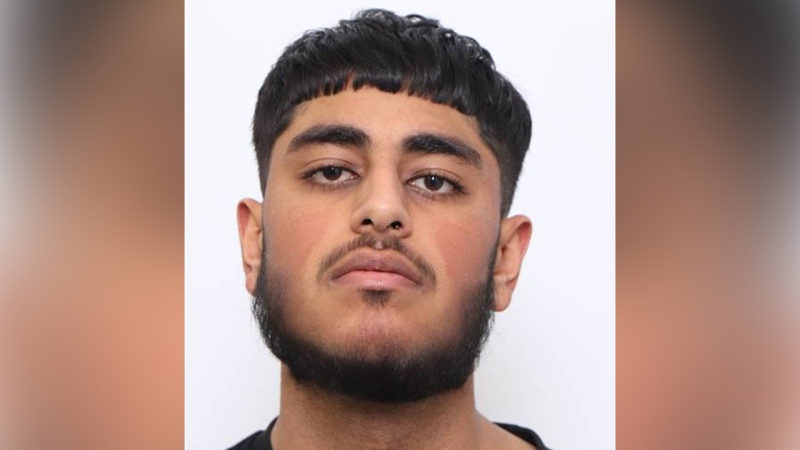

Baby, grandparents among 4 people killed in wrong-way police chase on Ontario's Hwy. 401

A police chase which started with a liquor store robbery in Bowmanville Monday night ended in tragedy some 20 minutes later when a suspect fleeing police entered Highway 401 in the wrong direction and caused a pileup which killed an infant and the child's grandparents, as well as the suspect, investigators say.

Air Canada walks back new seat selection policy change after backlash

Air Canada has paused a new seat selection fee for travellers booked on the lowest fares just days after implementing it.

McGill requests 'police assistance' over pro-Palestinian encampment

McGill University says it has 'requested police assistance' about the pro-Palestinian encampment on its lower field.

Judge raises threat of jail in hush money trial as he holds Trump in contempt, fines him US$9,000

Donald Trump was held in contempt of court Tuesday and fined US$9,000 for repeatedly violating a gag order that barred him from making public statements about witnesses, jurors and some others connected to his New York hush money case. And if he does it again, the judge warned, he could be jailed.

Court upholds Milwaukee police officer's firing for posting racist memes after Sterling Brown arrest

The Wisconsin Supreme Court ruled Tuesday that a former Milwaukee police officer was properly fired for posting racist memes related to the arrest of an NBA player that triggered a public outcry.

Video captures deadly wrong-way police chase on Highway 401 in Ontario

A new video has surfaced showing a vehicle being pursued by police in the wrong direction on Highway 401 moments prior to a fatal crash that killed four people, including an infant and their grandparents.

New cancer treatment approved, but not everyone thinks it's what's best for patients

A new cancer treatment recently approved in Canada promises to cut treatment time down to just minutes, but experts have differing opinions on whether it's what's best for patients.