KINGSTON -- Queen's University students are working to create a ventilator that can be made from easy to find parts, as part of an international competition to address the ventilator shortage during the COVID-19 pandemic.

And the team believes they’ve done it, in just ten short days.

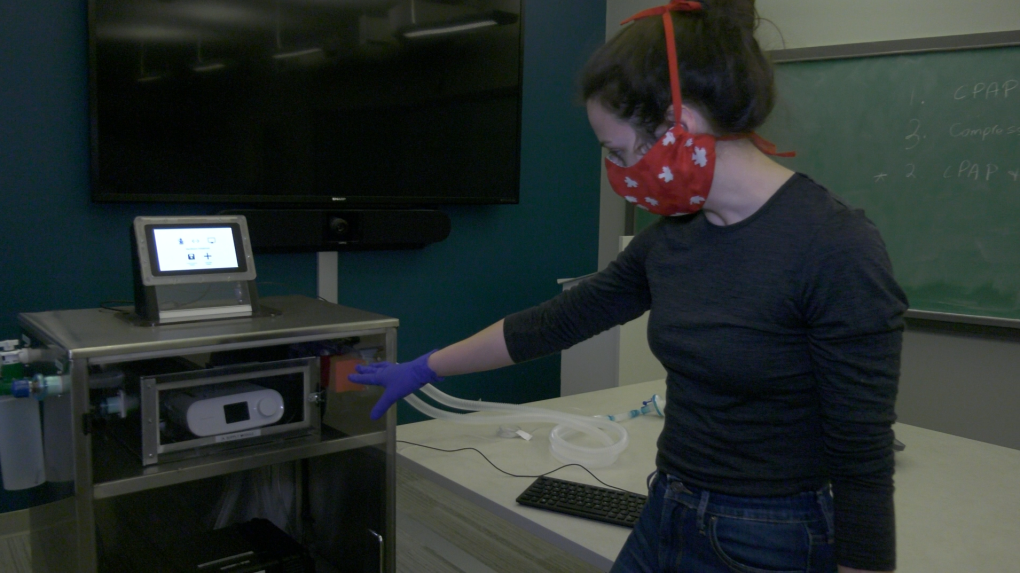

“We leaned heavily on medical devices that we could pull off the shelf to incorporate in our design, like the two CPAP machines, which are basically the heart of our design,” explains Heidi Ploeg, who is an associate professor in the Mechanical and Material Engineering Department at Queen's in Kingston.

CPAP machines are usually reserved for those suffering from sleep apnea, helping a patient breath better at night.

“These are pre-approved medical machines that are in wide use around the world, so they’re easy to access and manufacturing capabilities are high for the machines,” explains Sonya Pejcic, Masters Student in the Applied Sciences Department.

The project is being done for the "Code Life Ventilator Challenge" being put on by The Montreal General Hospital Foundation, and in collaboration with the Research Institute of the McGill University Health Centre.

It asks participants to design a “simple, low-cost, easy-to-manufacture and easy-to-maintain ventilator which could be deployed anywhere needed to save lives.”

Ventilators, which are devices that help a patient breath when their lungs are no longer capable of breathing on their own, are in short supply as the world battles the COVID-19 pandemic.

Pejcic says the premise behind their design is “do-it-yourself” with any parts that a hospital may have on hand.

“If someone wanted to re-create this and wasn’t able to get their hands on a CPAP, they could swap out either CPAP for anything that provides a constant pressure,” she explains. “So for example, the blowers that are used to pump up air mattresses, they could swap it out for this, as long as they meet that 20 centimetres of water pressure level of each machine.”

The team is hoping it’s one of the winners picked by the judges in the coming days. They say to see their machines in hospitals around the world would be a “dream.”

“I think it would be just fantastic to know that something that 20 people can cobble together in 10 to 15 days can really make an impact in the world,” says Pejcic.