Ottawa LRT is safe, city's transit head vows after TSB concerns

Ottawa's head of transit services vows the city's LRT system is safe after the federal transportation watchdog warned of ongoing safety risks.

"I want to be perfectly clear: the safety of our customers and my team is the number one priority," Renee Amilcar told the first-ever meeting of Ottawa's LRT subcommittee on Thursday.

"The O-Train is safe. If for any reason we believed that the train wasn't safe, we would not operate it."

In a letter dated Feb. 3 and released Wednesday, Transportation Safety Board issued a warning about the axle bearing assembly on Ottawa's Confederation Line trains. Problems with the assembly led to a derailment in August 2021 and additional problems in July 2022.

The TSB said the parts will "continue to pose a risk to safety" until OC Transpo and Rideau Transit Maintenance resolve the issues "to protect the travelling public."

Amilcar told councillors on Thursday that when OC Transpo received the letter, they took the time to review it and organize a meeting with Rideau Transit, Alstom, Rideau Transit Maintenance and the TSB to go over it and ensure the city had full clarity about the TSB's concerns.

"We have thoroughly reviewed the letter and ensured that the enhanced system safety measures currently in place align with the TSB suggestions," she said. "I can assure you that all the measures are in place …to ensure a safe and reliable train system," she said.

"I personally took the train yesterday from my house to the office," she added. "If I thought it was not safe, I would not have used it."

Amilcar also reiterated that the recent settlement with RTG included a plan of action to address the TSB's recommendations, and that RTG has provided written confirmation to the city that the system is safe.

"We asked for this letter," she said.

OC Transpo looking into heat detection

City staff shed more light on why they haven't installed a heat detection system on the trains despite the TSB's suggestion.

In September 2021, several weeks after the derailment caused by an "undetected catastrophic roller bearing failure" in the assembly, the agency recommended OC Transpo and RTM install heat detection systems to monitor temperatures of the assembly.

However, the TSB said this month "no concrete steps have been taken to resolve the safety deficiency identified" in that Rail Safety Advisory.

On Thursday, the city's director of engineering said the technology that exists wouldn't be suitable for light rail trains.

"Heat detection technology is common and familiar within Canada and across North America, but it is common within heavy freight," Richard Holder said. "As far as we are aware, there are no examples of heat detection being employed on a light rail system."

He also said in the case of the August 2021 derailment, the heat detection system would have been too late to prevent the derailment.

"Even if heat detection had been in place at that time, and provided a trigger that the axle was getting hot, it would have been too late," he said. "The failure would have occurred. That has been the position for many, many months."

Instead, the city and RTG implemented a pilot project to test an on-board sensor to measure vibration to provide early-warning signals, rather than heat.

However, the TSB's recent letter has changed that stance. The TSB found that elevated heat led to the bearing failure in July 2022, when an operator felt unusual vibration on a train.

As a result, the city is "actively looking now at what heat detection technologies are out there that we can apply to a light rail system," Holder said.

Current measures not sustainable

Right now, maintenance staff inspect the parts every 7,500 kilometres and replace them every 175,000 kilometres. They are supposed to last 1.2 million kilometres.

Trains are also inspected every morning. There are also temporary speed restrictions on several stretches of the track—particularly curves—to reduce the overall forces on the axles.

But Amilcar admitted those measures aren't sustainable for the long term.

"With the risk, comes mitigation measures, and we have the measures in place- but they are not sustainable in the long term, because we need a lot of workmanship, and we want to make sure we have a final fix in order to apply to the entire fleet and Stage 2," Amilcar said.

OC Transpo playing "catch up" with axle bearings

What is causing the issues with the axle bearings still isn’t clear.

Holder says RTG is still trying to figure out the cause.

"The purpose of that root cause analysis is to determine precisely what are the causes for the failures that we have been seeing," Holder said.

"There is an overall understanding that it is going to be related to the design of the axle, to the conditions on the track, to the geometry of the track. There is an interaction at play between the boogies, the vehicles, and the track infrastructure that is causing this overall issue of the failures of the materials."

Holder says, "Once we have a root cause analysis, which identifies what the problem is, an action plan will be created to make changes both on the track side but also on the vehicle side."

Holder says the city has taken measures to fix problems on the rails and says problems will always occur on a large-scale project like the LRT.

"There always will be measures in place to ensure the safety of the travelling public, so there are hazards and risks associated with huge infrastructure projects, such as the LRT project. We are constantly responding to how the system is performing and if we need to make changes to the system, we will do that."

However, Holder admits the city is playing "catch up" with the axle bearings.

"You are correct to say we are in 'catch up' mode now with the axle bearing issue. But the plan is to find a solid solution so that we have a permanent fix."

Despite the constant problems with the trains, Amilcar says there are no plans to replace the trains.

"At this time, I have no reason to think we have to change the train, but at the end of the day it is Alstom who will make that decision because it is their vehicle," Amilcar said.

"I think it is more important than ever to have a root cause analysis to make sure the final decision is the right one."

Michael Morgan, director of the city’s rail construction, says lesson learned from issues on Stage 1 have already led to changes with Stage 2 construction.

"We have made design changes generally from lessons learned in Stage 1, they are incorporated. The things that may come out of the root cause, like the profile of the railhead- you could update with a rail grinder," Morgan said. "So the fixes that we are talking about with the geometry or wheel-rail interface could be applied to the infrastructure so we are going ahead and building the infrastructure. If we need to come back with a grinding machine and fix that, we will."

But Morgan says there are no plans to "rip up the track".

Morgan says, "The track uses standard rails, standard ties, standard clips- it is a standard design. The changes that you make, or that we have been looking to make out of Stage 1, are adjustment to the rail neutral temperature – so the laying temperatures of the rail, to be able to deal with the hot summers; making sure the foundation, the ballast is built corrective to deal with tight curve. Those are all things we are applying to Stage 2, there is no obvious path forward to having to rip up the tracks completely."

CTVNews.ca Top Stories

Widow looking for answers after Quebec man dies in Texas Ironman competition

The widow of a Quebec man who died competing in an Ironman competition is looking for answers.

Tom Mulcair: Park littered with trash after 'pilot project' is perfect symbol of Trudeau governance

Former NDP leader Tom Mulcair says that what's happening now in a trash-littered federal park in Quebec is a perfect metaphor for how the Trudeau government runs things.

World seeing near breakdown of international law amid wars in Gaza and Ukraine, Amnesty says

The world is seeing a near breakdown of international law amid flagrant rule-breaking in Gaza and Ukraine, multiplying armed conflicts, the rise of authoritarianism and huge rights violations in Sudan, Ethiopia and Myanmar, Amnesty International warned Wednesday as it published its annual report.

Photographer alleges he was forced to watch Megan Thee Stallion have sex and was unfairly fired

A photographer who worked for Megan Thee Stallion said in a lawsuit filed Tuesday that he was forced to watch her have sex, was unfairly fired soon after and was abused as her employee.

Amid concerns over 'collateral damage' Trudeau, Freeland defend capital gains tax change

Facing pushback from physicians and businesspeople over the coming increase to the capital gains inclusion rate, Prime Minister Justin Trudeau and his deputy Chrystia Freeland are standing by their plan to target Canada's highest earners.

U.S. Senate passes bill forcing TikTok's parent company to sell or face ban, sends to Biden for signature

The Senate passed legislation Tuesday that would force TikTok's China-based parent company to sell the social media platform under the threat of a ban, a contentious move by U.S. lawmakers that's expected to face legal challenges.

Wildfire southwest of Peace River spurs evacuation order

People living near a wildfire burning about 15 kilometres southwest of Peace River are being told to evacuate their homes.

U.S. Senate overwhelmingly passes aid for Ukraine, Israel and Taiwan with big bipartisan vote

The U.S. Senate has passed US$95 billion in war aid to Ukraine, Israel and Taiwan, sending the legislation to President Joe Biden after months of delays and contentious debate over how involved the United States should be in foreign wars.

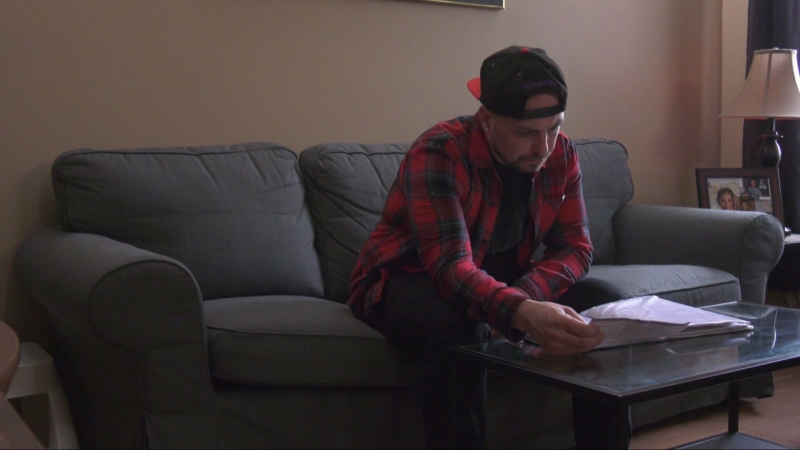

'My stomach dropped': Winnipeg man speaks out after being criminally harassed following single online date

A Winnipeg man said a single date gone wrong led to years of criminal harassment, false arrests, stress and depression.